Tawîzên Buhayê Avakirina Lûleyên Pola Z yên Sar ên Çînê Bi piranî di Avakirinê de Têne Bikaranîn

PÊVAJOYA HILBERÎNA BERHEMÊ

Pêvajoya hilberîna alavên sar-formkirîpîlê pelê pola yê cureya zbi gelemperî gavên jêrîn dihewîne:

Amadekirina materyalan: Materyalên plakaya pola yên ku hewcedariyan pêk tînin hilbijêrin, bi gelemperî plakayên pola yên germ-gêrkirî an sar-gêrkirî, û li gorî hewcedarî û standardên sêwiranê materyalan hilbijêrin.

Birîn: Plaqeya pola li gorî hewcedariyên sêwirandinê bibirin da ku valahiyek plakaya pola were bidestxistin ku şertên dirêjahiyê bicîh bîne.

Çemandina Sar: Valahiya plakaya pola ya birrî ji bo pêvajoya şekildanê tê şandin makîneya şekildana sar. Plakaya pola bi pêvajoyên wekî gêrkirin û xwarkirinê bi sar ve tê çemandin û dibe beşek xaçerêyî ya bi şiklê Z.

Qayimkirin: Pîlên pola yên bi şiklê Z-yê yên sar-çêkirî bi qayimkirinê ve biqelînin da ku pê ewle bibin ku girêdanên wan saxlem û bê kêmasî ne.

Dermankirina rûvî: Dermankirina rûvî li ser pîlên pola yên bi şiklê Z-yê yên qelandî têne kirin, wek rakirina zengarê, boyaxkirin û hwd., da ku performansa wê ya dij-korozyonê baştir bibe.

Teftîş: Teftîşa kalîteyê li ser pilên pelên pola yên bi şiklê Z yên sar-şekilkirî yên hilberandî bikin, tevî teftîşa kalîteya xuyangê, guherîna pîvanî, kalîteya weldingê, û hwd.

Pakkirin û derketina ji kargehê: Pîlên pola yên bi şiklê Z yên sar-şekilkirî yên kalîfîye têne pakkirin, bi agahdariya hilberê têne nîşankirin, û ji bo hilanînê ji kargehê têne şandin.

*E-nameyê ji vê navnîşanê re bişîne[email protected]ji bo wergirtina pêşniyarek ji bo projeyên xwe

Bilindahiya (H) ya stûnên pelên pola yên bi şiklê Z bi gelemperî ji 200 mm heta 600 mm diguhere.

Firehiya (B) ya stûnên pelê pola yên bi şiklê Z yên Q235b bi gelemperî ji 60 mm heta 210 mm diguhere.

Qalindahiya (t) ya stûnên pelên pola yên bi şiklê Z bi gelemperî ji 6 mm heta 20 mm diguhere.

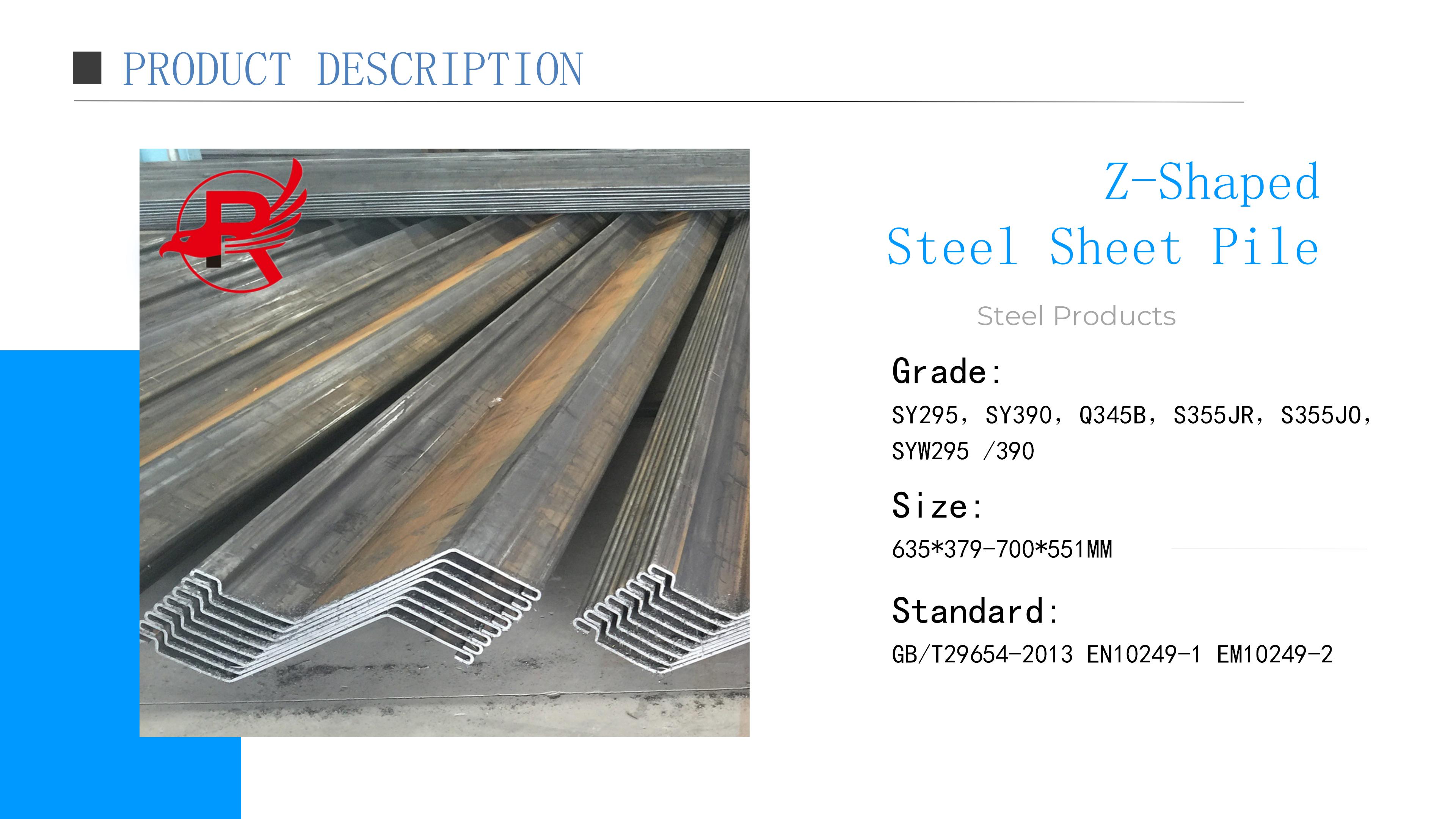

| TAYBETMENDIYÊN JI BOPîlê Pelê Z | |

| 1. Mezinahî | 1) 635*379—700*551mm |

| 2) Stûriya Dîwar:4—16MM | |

| 3)Zpileya pelê tîpan | |

| 2. Standard: | GB/T29654-2013 EN10249-1 |

| 3.Materyal | Q235B Q345B S235 S240 SY295 S355 S340 |

| 4. Cihê kargeha me | Tianjin,Çîn |

| 5. Bikaranîn: | 1) wesayîtên gerok |

| 2) Avakirina avahiya pola | |

| 3Tepsiya kabloyê | |

| 6. Rûpûşkirin: | 1) Tazîkirî 2) Reş Boyaxkirî (boyaxkirina vernîk) 3) Galvanîzekirî |

| 7. Teknîk: | germ pêçayî |

| 8. Cure: | Zpileya pelê tîpan |

| 9. Şêweya Beşê: | Z |

| 10. Teftîşkirin: | Muayeneya xerîdar an muayeneya ji hêla partiya 3-an ve. |

| 11. Radestkirin: | Konteyner, Keştiya barkêşiya girseyî. |

| 12. Derbarê Kalîteya Me de: | 1) Bê zirar, ne xwar 2) Bê rûn û nîşankirin 3) Hemû kelûpel dikarin berî barkirinê ji hêla teftîşa partiya sêyemîn ve werin kontrol kirin |

*E-nameyê ji vê navnîşanê re bişîne[email protected]ji bo wergirtina pêşniyarek ji bo projeyên xwe

| Liq | Berî | Bilindî | Qewîtî | Rûbera Beşa Çarçoveyî | Pîvan | Modula Beşa Elastîk | Gava Bêçalakiyê | Rûbera Rûpûşkirinê (her du alî li ser her stûnê) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (w) | (h) | Flange (tf) | Web (tw) | Ji bo her stûnê | Li ser dîwar | |||||

| mm | mm | mm | mm | cm²/m | kg/m | kg/m² | cm³/m | cm4/m | m²/m | |

| CRZ12-700 | 700 | 440 | 6 | 6 | 89.9 | 49.52 | 70.6 | 1,187 | 26,124 | 2.11 |

| CRZ13-670 | 670 | 303 | 9.5 | 9.5 | 139 | 73.1 | 109.1 | 1,305 | 19,776 | 1.98 |

| CRZ13-770 | 770 | 344 | 8.5 | 8.5 | 120.4 | 72.75 | 94.5 | 1,311 | 22,747 | 2.2 |

| CRZ14-670 | 670 | 304 | 10.5 | 10.5 | 154.9 | 81.49 | 121.6 | 1,391 | 21,148 | 2 |

| CRZ14-650 | 650 | 320 | 8 | 8 | 125.7 | 64.11 | 98.6 | 1,402 | 22,431 | 2.06 |

| CRZ14-770 | 770 | 345 | 10 | 10 | 138.5 | 83.74 | 108.8 | 1,417 | 24,443 | 2.15 |

| CRZ15-750 | 750 | 470 | 7.75 | 7.75 | 112.5 | 66.25 | 88.34 | 1,523 | 35,753 | 2.19 |

| CRZ16-700 | 700 | 470 | 7 | 7 | 110.4 | 60.68 | 86.7 | 1,604 | 37,684 | 2.22 |

| CRZ17-700 | 700 | 420 | 8.5 | 8.5 | 132.1 | 72.57 | 103.7 | 1,729 | 36,439 | 2.19 |

| CRZ18-630 | 630 | 380 | 9.5 | 9.5 | 152.1 | 75.24 | 119.4 | 1,797 | 34,135 | 2.04 |

| CRZ18-700 | 700 | 420 | 9 | 9 | 139.3 | 76.55 | 109.4 | 1,822 | 38,480 | 2.19 |

| CRZ18-630N | 630 | 450 | 8 | 8 | 132.7 | 65.63 | 104.2 | 1,839 | 41,388 | 2.11 |

| CRZ18-800 | 800 | 500 | 8.5 | 8.5 | 127.2 | 79.9 | 99.8 | 1,858 | 46,474 | 2.39 |

| CRZ19-700 | 700 | 421 | 9.5 | 9.5 | 146.3 | 80.37 | 114.8 | 1,870 | 39,419 | 2.18 |

| CRZ20-700 | 700 | 421 | 10 | 10 | 153.6 | 84.41 | 120.6 | 1,946 | 40,954 | 2.17 |

| CRZ20-800 | 800 | 490 | 9.5 | 9.5 | 141.2 | 88.7 | 110.8 | 2,000 | 49,026 | 2.38 |

Rêzeya Modula Beşê

1100-5000cm3/m

Rêzeya firehiyê (yekane)

580-800mm

Rêzeya Stûriyê

5-16mm

Standardên Hilberînê

BS EN 10249 Beşa 1 û 2

Pola Pola

S235JR, S275JR, S355JR, S355JO

ASTM A572 Gr42, Gr50, Gr60

Q235B, Q345B, Q345C, Q390B, Q420B

Yên din li ser daxwazê berdest in

Dirêjî

Herî zêde 35.0m lê her dirêjahiya taybetî ya projeyê dikare were hilberandin

Vebijarkên Radestkirinê

Yekane an Cot

Cot yan sist, yan qelandî yan jî pêçayî ne

Çala Hildanê

Plaqeya Girtinê

Bi konteyner (11.8m an kêmtir) an jî bi perçeyên barkirî

Rûpûşên Parastina Korozyonê

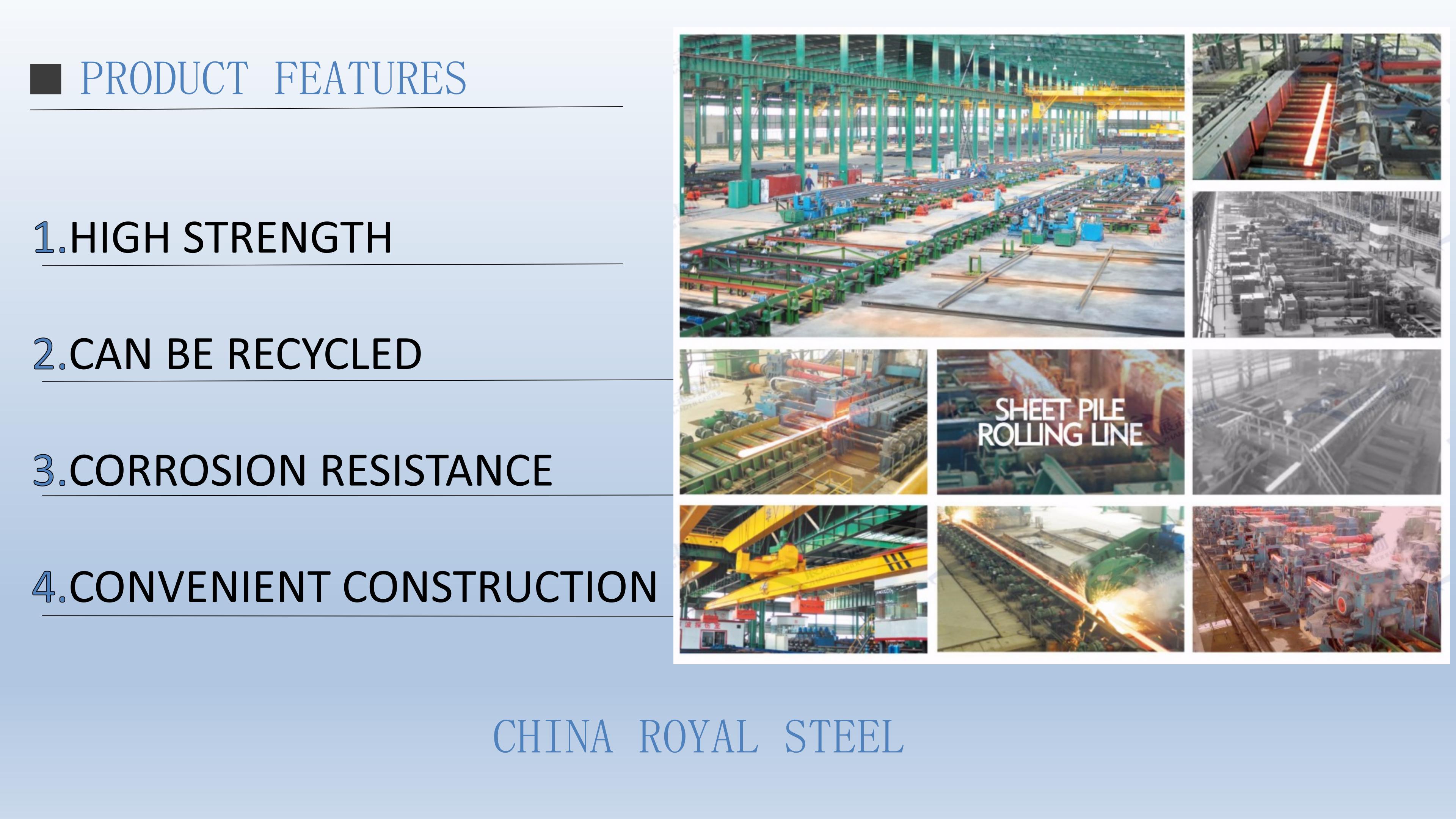

TAYBETMENDÎ

Ewpileya pelê cureya zavahiyek pola ye ku bi berdewamî ji hêla yekîneya şekildana sar ve tê pêçandin û çêkirin, û kilîda alî dikare bi berdewamî were girêdan da ku dîwarek pileya pelan çêbike. Pileya pelên pola ya şekildana sar ji pelên zirav (stûriya asayî 8mm ~ 14mm e) tê çêkirin û ji hêla yekîneya şekildana sar ve tê pêvajokirin.

Taybetmendiyên pileya pelê pola: Li gorî rewşa rastîn a projeyê, beşa herî aborî û maqûl dikare were hilbijartin da ku sêwirana endezyariyê baştir bibe.

![V~BQZ}N`UF@KMR]XTP$DYPW](http://www.chinaroyalsteel.com/uploads/VBQZNUF@KMRXTPDYPW.png)

BIKARANÎNÎ

1. Firehiya mezin a beşê misoger dike ku taybetmendiyên mekanîkî yên beşê bi tevahî têne lîstin.

2. Avahiya sîmetrîk, ji nû ve bikaranîna wê hêsan e.

3. Sêwirana avahiya beşa hilberê maqûl e, bi "koefîsyentek kalîteyê" ya bilind

4. Bikaranînapîvanên pelê zşert û mercên hewayê nikarin werin sînordarkirin;

5. Avakirin bandorek girîng li ser parastina jîngehê dike, pir kêm dike mîqdara axê û karanîna betonê, bi bandor çavkaniyên erdê diparêze;

6. Kesk be.

![0$NU_O5TD8Y4}`E3UXEVP]2](http://www.chinaroyalsteel.com/uploads/0NU_O5TD8Y4E3UXEVP2.jpg)

PAKETKIRIN Û ŞANDIN

Rêzeya sepandinapileya pelên pola

1, bendava qefesê, endezyariya benderê

Ji ber hişkbûn û berxwedana xwe ya bilind, polayê dikare bi berfirehî di projeyên li beravên çem, bendava qefesan, bendergehê û projeyên din de were bikar anîn da ku piştgirî û parastinek xurt peyda bike.

2, tunelên metroyê, kargeh û projeyên din

dîwarê stûnê pelê polaher wiha dikare di tunelên metroyê, kargeh û projeyên din ên avakirinê de jî were bikar anîn. Ji ber pêvajoya wê ya hêsan û sazkirina wê ya hêsan, ew dikare rehetiyek mezin bîne avakirina endezyariyê.

3. Avakirina şaredariyê

Di avakirina şaredariyê de, pîlên pelên pola dikarin wekî pêkhateyên piştgir û parastinê ji bo rê, pir û tunelan werin bikar anîn, û dikarin di berfirehkirina parastina avê, dabînkirina avê, rêkûpêkkirina çeman û warên din de alîkariya şaredariyan bikin.

SERDANÊN MIŞTERÎ

Li Çînê hatî çêkirin, karûbarê pola yekem, kalîteya pêşkeftî, navdarê cîhanê

1. Bandora pîvanê: Şîrketa me xwediyê zincîreke dabînkirinê ya mezin û kargeheke pola ya mezin e, di veguhastin û kirînê de bandorên pîvanê bi dest dixe, û dibe şîrketeke pola ku hilberîn û xizmetguzariyan entegre dike.

2. Cûrbecûrîya berheman: Cûrbecûrîya berheman, her pola ku hûn dixwazin dikare ji me were kirîn, bi giranî di strukturên pola, rayên pola, pilên pelên pola, braketên fotovoltaîk, pola kanalê, bobînên pola silîkonê û berhemên din de mijûl dibe, ku ev yek wê nermtir dike. Cureyê berhema xwestî hilbijêrin da ku hewcedariyên cûda bicîh bînin.

3. Dabînkirina stabîl: Hebûna xeta hilberînê û zincîra dabînkirinê ya stabîltir dikare dabînkirina pêbawertir peyda bike. Ev bi taybetî ji bo kirrûbirên ku hewceyê mîqdarên mezin ên pola ne girîng e.

4. Bandora Brandê: Xwedî bandorek mezintir a marqeyê û bazarek mezintir be

5. Xizmet: Şîrketeke mezin a pola ku xwerûkirin, veguhastin û hilberînê entegre dike

6. Reqabetbariya bihayê: bihayê maqûl

*E-nameyê ji vê navnîşanê re bişîne[email protected]ji bo wergirtina pêşniyarek ji bo projeyên xwe

SERDANÊN MIŞTERÎ

Dema ku xerîdarek bixwaze serdana hilberekê bike, bi gelemperî gavên jêrîn dikarin werin rêzkirin:

Randevûyekê ji bo serdanê çêbikin: Xerîdar dikarin ji bo diyarkirina dem û cihê serdana hilberê, pêşwext bi hilberîner an nûnerê firotanê re têkilî daynin.

Rêkxistina geşteke bi rêberî: Pispor an nûnerên firotanê wekî rêberên geştyarî erkdar bikin da ku pêvajoya hilberînê, teknolojiyê û pêvajoya kontrolkirina kalîteyê ya hilberê nîşanî xerîdaran bidin.

Berheman nîşan bide: Di dema serdanê de, berheman di qonaxên cuda de nîşanî xerîdaran bide da ku xerîdar pêvajoya hilberînê û pîvanên kalîteyê yên berheman fêm bikin.

Bersiva pirsan bidin: Di dema serdanê de, dibe ku xerîdar pirsên cûrbecûr hebin, û rêberê geştyarî an nûnerê firotanê divê bi sebir bersiva wan bide û agahdariya teknîkî û kalîteyê ya têkildar peyda bike.

Nimûneyan peyda bikin: Heke gengaz be, nimûneyên hilberê dikarin ji xerîdaran re werin peyda kirin da ku xerîdar bikaribin kalîte û taybetmendiyên hilberê bi awayekî çêtir fam bikin.

Şopandin: Piştî serdanê, tavilê li gorî nerîn û pêdiviyên xerîdaran tevbigerin da ku piştgirî û karûbarên din ji xerîdaran re peyda bikin.

Pirsên Pir tên Pirsîn

Q1: Şîrketa we çi cure karî dike?

A1: Em bi giranî piles pelên pola / rails / pola silicon / pola şikilandî, û hwd. hildiberînin.

Q2: Dema radestkirina we çiqas e?

A2: Bi gelemperî 5-10 roj e heke kelûpel di stokê de bin. An jî heke kelûpel di stokê de nebin, 15-20 roj li gorî

jimarî.

Q3: Feydeyên pargîdaniya we çi ne?

A3: Şîrketa me tîmek profesyonel û xetên hilberîna profesyonel heye.

Q4: Ma hûn şîrketek bazirganî ne an jî çêkerek?

A4: Em fabrîqe ne.

Q5: Mercên dayîna we çi ne?

A5: Pere <=1000USD, 100% pêşwext. Pere >=1000 USD, 30% T/T pêşwext,

Heke pirsên we yên din hebin, ji kerema xwe bi rêbazên jêrîn bi me re têkilî daynin.