API 5CT N80 P110 Q125 J55 Lûleya pola ya bêderz a octg 24 înç a rûnê û lûleya lûleya pola karbonê ya petrolê A53 A106 bihayê lûleya lûleya pola karbonê

Hûrguliyên Berhemê

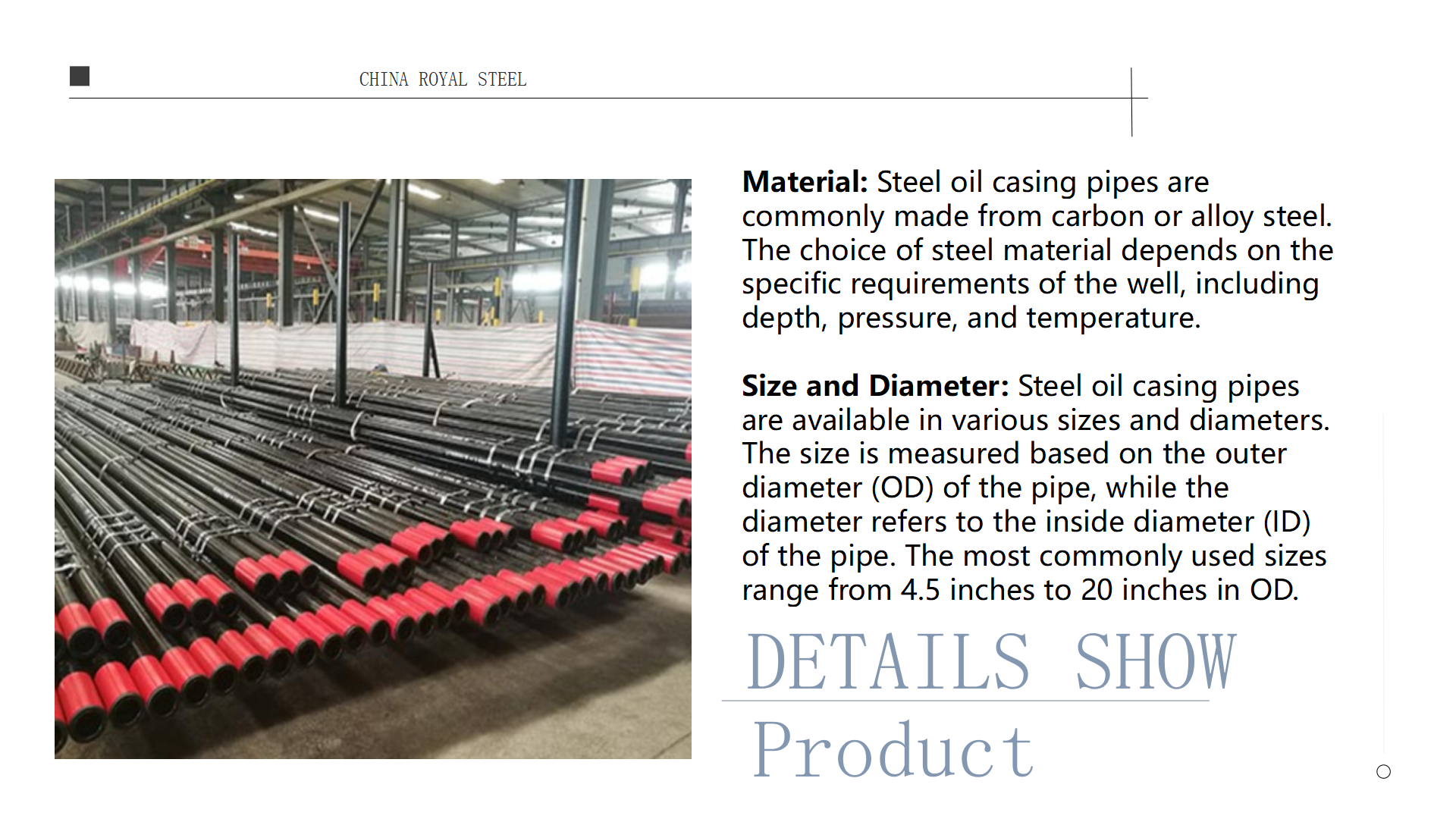

Borîyên qalikê yên petrolê yên pola bi gelemperî bênavber an jî bi qayîmkirî ne û bi mezinahî û dirêjahîyên cûrbecûr têne da ku li gorî hewcedariyên kolandinê yên cûda bin. Ew hatine sêwirandin da ku li dora bîrê astengiyeke parastinê çêbikin, û di qonaxên kolandinê, temamkirinê û hilberînê de aramî û yekparebûna bîrê misoger bikin.

Armanca sereke ya boriyên qapaxên petrolê ew e ku pêşî li hilweşîna bîrê bigirin, formasyonên cûda îzole bikin, û herikîna petrol an gazê ber bi rûyê erdê ve kontrol bikin. Ev boriyan di heman demê de piştgirî didin alavên sondajê û sazkirina pêkhateyên din ên temamkirinê yên wekî qapax, lûle û pakeker hêsan dikin.

| Berhem | Boriya pola/lûle | ||

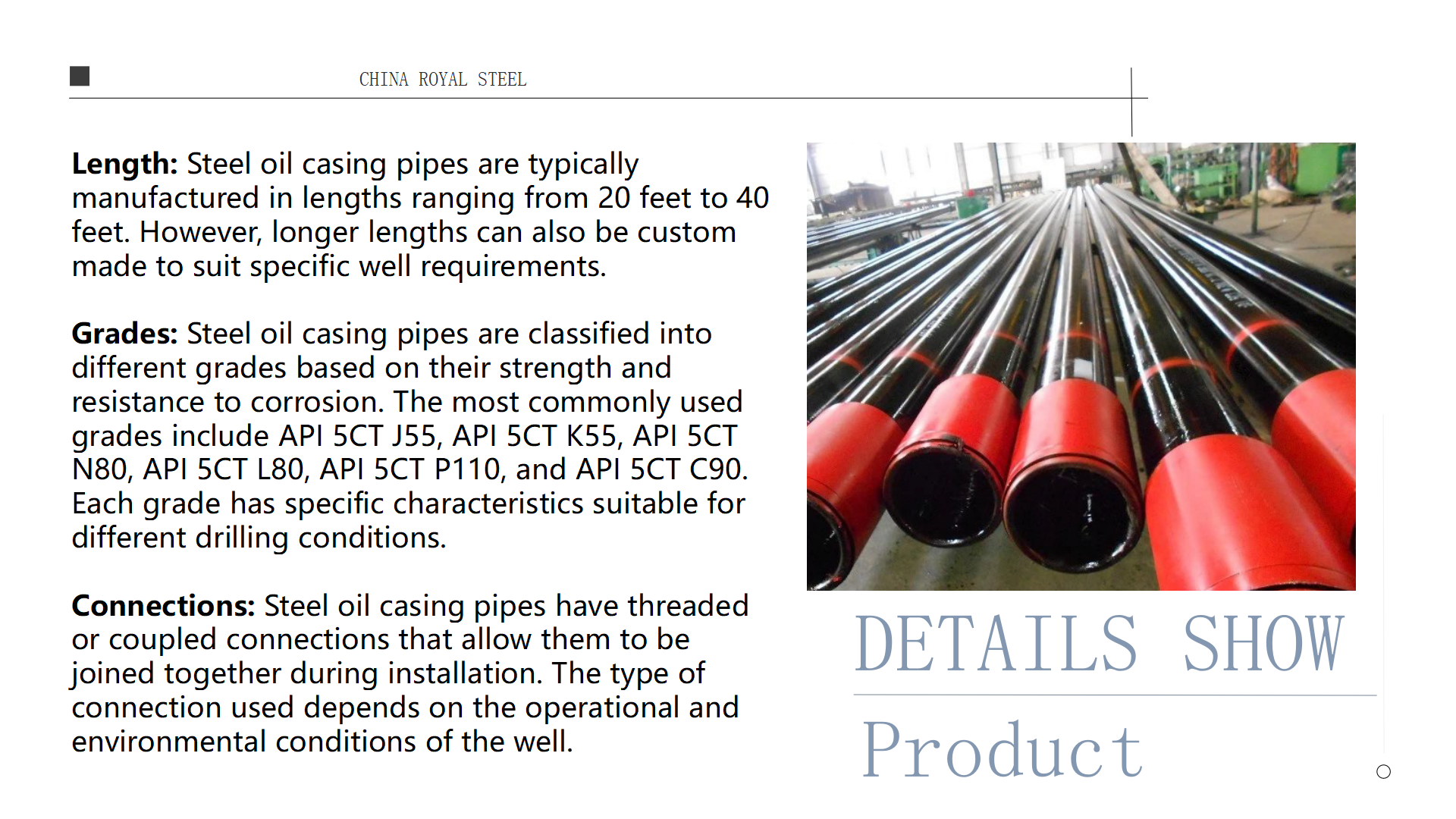

| Rêzan | API 5CT PSL1/PSL2 J55, K55, N80-1, N80-Q, L245, L360, X42, X52, X60, X70. API 5CT PSL1/PSL2 L80-1, L80-9Cr, L80-13Cr, C90, C95, P110, Q125 | ||

| Mal | ST37/ST45/ST52/25Mn/27SiMn/E355/SAE1026/STKM13C | ||

| Dirêjahiya derve | 114.3mm-508mm an jî xwerû | ||

| Qalindahiya dîwar | 5-16mm an jî xwerû | ||

| Dirêjî | 5.8m, 6-12m an jî li gorî pêwîstiyê | ||

| Dermankirina rûberê | Reş/Qelişandin/Cilkirin/Makînkirî | ||

| Dermankirina germê | Germkirî; Temirandî; Tehmdarkirî | ||

Taybetmendî

Hêz û domdarî: Borîyên qalikê yên pola ji pola bi kalîte bilind têne çêkirin, ku hêz û domdariyek hêja peyda dike. Ev dihêle ku ew li hember zextên bilind, jîngehên korozîf û şert û mercên din ên dijwar ên ku di operasyonên sondajên petrol û gazê de têne dîtin, li ber xwe bidin.

Avakirina bêderz an qayîmkirî: Lûleyên qalikê rûnê pola hem bi bêderz û hem jî bi qayîmkirî hene. Lûleyên bêderz bêyî qayîmkirin têne çêkirin, ku ev jî xalên lawaz ên potansiyel ji holê radike. Lûleyên qayîmkirî bi girêdana beşên pola bi karanîna teknîkên qayîmkirinê têne çêkirin, ku vebijarkek lêçûn-bandor peyda dike.

Mezinahî û dirêjahîyên cûrbecûr: Borîyên pola yên qalikê rûnê bi mezinahî û dirêjahîyên cûda têne da ku hewcedariyên kolandinê yên cûda bicîh bînin. Mezinahî û dirêjahiya borîyan li gorî faktorên wekî kûrahiya bîrê, taybetmendiyên avakirinê û teknîkên kolandinê têne hilbijartin.

Berxwedana li hember korozyonê: Borîyên pola yên qalikê rûnê bi gelemperî bi materyalên dij-korozyonê têne pêçandin an boyaxkirin da ku wan ji hêmanên korozîf ên ku di dema operasyonên kolandinê de rastî wan tên biparêzin. Ev yek dibe alîkar ku temenê boriyan dirêj bibe û yekparçeyiya avahiya wan were parastin.

Hilberîna standardkirî: Borîyên pola yên qalikê rûnê li gorî standard û taybetmendiyên pîşesaziyê yên wekî standardên API (Enstîtuya Petrolê ya Amerîkî) têne çêkirin. Ev yek piştrast dike ku boriyan hin şertên kalîte û performansê bicîh tînin.

Girêdanên bi têl an jî bi hev ve girêdayî: Boriyên qalikê petrolê yên pola bi girêdanên bi têl an jî bi hev ve girêdayî têne sêwirandin ku sazkirin û ji hev veqetandina wan hêsan dike. Ev girêdan mohreke ewle û neherikbar peyda dikin, û yekparçeyiya bîrê misoger dikin.

Lihevhatina bi pêkhateyên din re: Lûleyên qapaxa rûnê yên pola ji bo ku bi pêkhateyên din ên temamkirinê yên wekî qapax, lûle û pakkeran re lihevhatî bin hatine çêkirin. Ev yek dihêle ku van pêkhateyan bi bandor û bênavber entegre bibin, û operasyonên kolandin û hilberînê hêsan bikin.

Bikaranînî

Borîyên qalikê yên rûnê yên pola bi giranî di pîşesaziya petrol û gazê de ji bo cûrbecûr serlêdanan têne bikar anîn, di nav de:

Aramiya bîrê: Boriyên qalikê di dema operasyonên kolandinê de têne danîn da ku yekparebûna avahiya bîrê peyda bikin. Ew wekî piştgiriyek tevdigerin û pêşî li hilweşîna dîwarên bîrê digirin, û aramî û ewlehiya pêvajoya kolandinê misoger dikin.

Ragirtina şilavên sondajê: Boriyên qapaxê di dema operasyonên sondajê de dibin alîkar ku herikîna şilavên sondajê (wek herrî û çîmento) were kontrol kirin. Ew rê li ber rijandina şilavan an gemarîkirina formasyonên derdorê an jî çavkaniyên avê digirin.

Pêşîgirtina li teqîna bîran: Boriyên qapaxê di pêşîgirtina li teqîna bîran de roleke girîng dilîzin, ku ev dikare xeternak û biha be. Qapax astengiyek di navbera bîrê û formasyonên derdorê de peyda dike, û rê li ber berdana bêkontrol a petrol, gaz, an şilavên sondajê digire.

Hilberîn û derxistina şilavê: Lûleyên qalikê ji bo derxistina petrol, gaz û şilavên din ji rezervuaran têne bikar anîn. Ew bi beşên qulkirî an jî qulkirî ve têne çêkirin ku dihêlin şilav ji rezervuarê biherikin nav bîrê.

Parastina li dijî korozyonê: Boriyên qalikê ji bo ku li hember jîngehên korozîf ên ku di operasyonên sondajên petrol û gazê de çêdibin li ber xwe bidin hatine çêkirin. Ew bi materyalên dijî-korozyonê têne pêçandin an boyaxkirin da ku li hember bandorên korozîf ên şilavên sondajê û jîngeha derdorê werin parastin.

Ragirtina zextê: Lûleyên qalikê ji bo ku li hember jîngehên zexta bilind ên ku di dema operasyonên kolandin û hilberînê de çêdibin li ber xwe bidin hatine çêkirin. Ew li hember zextên bilind ên ku ji hêla şilavên rezervuarê ve têne çêkirin, astengiyek peyda dikin, ewlehî û yekparebûna bîrê misoger dikin.

Çîmentokirin û îzolekirina herêman: Boriyên qalikê di pêvajoya çîmentoyê de têne bikar anîn da ku di navbera bîrê û formasyonên derdorê de mohrek çêbikin, û rê li ber koçberiya şilavê di navbera herêmên cûda de bigirin. Ev yek dibe alîkar ku yekparçeyiya bîrê were parastin û pêşî li gemarbûna şilavê bigire.

Temamkirina bîrê: Borîyên qalikê wekî lûleyek ji bo pêkhateyên din ên temamkirinê, wek lûle, pakker û alavên hilberînê, xizmet dikin. Ew sazkirin û xebitandina van pêkhateyan hêsantir dikin, û rê didin temamkirina bîrê û çalakiyên hilberînê yên bi bandor.

Pêvajoya Hilberînê

Pêvajoya hilberîna qapaxên petrolê ji çend qonaxan pêk tê. Li vir nirxandinek giştî ya pêvajoya hilberîna qapaxên petrolê heye:

Çêkirina pola: Gava yekem hilberîna pola bi kalîte ye ku ji bo çêkirina boriyên qalikê tê bikar anîn. Pola di kargehên pola de bi rêya pêvajoyên wekî helandin, rafinandin û hişkkirinê tê hilberandin.

Çêkirina boriyan: Di vê gavê de, pola bi rêbazên cûrbecûr, di nav de çêkirina boriyên bêderz an teknîkên kaynakirina dirêjahî û spiral, dibe boriyan. Boriyên bêderz bi qulkirina perçeyek pola ya zexm têne çêkirin, lê boriyên kaynakirî bi girêdana şerîtên pola bi karanîna rêbazên kaynakirinê têne çêkirin.

Dermankirina germê: Piştî ku boriyan tên çêkirin, ew ji bo baştirkirina taybetmendiyên xwe yên mekanîkî di pêvajoyek dermankirina germê re derbas dibin. Dermankirina germê germkirina boriyan heta germahiyek diyarkirî û dûv re sarkirina wan a bilez ji bo baştirkirina hêz, hişkbûn û berxwedana wan a li hember korozyonê vedihewîne.

Çêkirina lûleyên qapaxê: Çêkirina lûleyan gaveke girîng e di hilberîna qapaxên petrolê de. Serê lûleyên qapaxê têne çekirin da ku di dema çêkirina bîrê de girêdanên di navbera wan de gengaz bibin. Çêkirina lûleyan dikare bi karanîna pêvajoyên cûrbecûr ên çekirinê were kirin, di nav de girêdanên milê zivirî an girêdanên lûleyên konîk.

Kontrol û Vekolîna Kalîteyê: Borîyên qalikê pêvajoyên kontrol û vekolîna kalîteyê yên dijwar derbas dikin. Ev kontrolên pîvanî, vekolîna dîtbarî, ceribandina perçeyên ultrasonîk an magnetîkî, û rêbazên din ên ceribandina ne-wêranker vedihewîne da ku piştrast bike ku boriyên li gorî taybetmendî û pîvanên kalîteyê yên pêwîst in.

Pêçandin û qedandin: Borîyên qalibê pir caran têne pêçandin da ku wan ji korozyonê biparêzin û temenê wan dirêj bikin. Materyalên pêçandinê yên wekî epoksî, polîetîlen, an çînko bi rêbazên wekî galvanîzasyona germ-dip an sepandina pêçandinê li ser rûyê derveyî yê boriyan têne sepandin. Ev pêvajoya pêçandinê berxwedana korozyonê ya zêdetir peyda dike û piştrast dike ku boriyên ji bo bicihkirinê di bîrên petrol û gazê de amade ne.

Pakkirin û şandin: Dema ku boriyan pêvajoyên kontrolkirina kalîteyê û pêçandinê derbas dikin, ew têne pakkirin û ji bo şandina ji xerîdaran re têne amadekirin. Bi gelemperî boriyan têne pakkirin, bi kemer têne girêdan û têne parastin da ku di dema veguhastinê de zirarê nebînin.

Pakkirin û Şandin

Pirsên Pir tên Pirsîn

1. Em kî ne?

Navenda me li Tianjin, Çînê ye, û zêdetirî 10 salan e ku em di pîşesaziya hinardekirina pola de pispor in, û şaxên me li Dewletên Yekbûyî, Ekvador, Guatemala û welatên din hene.

2. Em çawa kalîteyê misoger dikin?

Berî hilberîna girseyî her tim nimûneyên pêş-hilberînê hene;

Berî barkirinê her tim teftîşa dawî bikin;

3. Hûn dikarin ji me çi bikirin?

Braketên fotovoltaîk, pîlên pelên pola, pola silîkonî, lûleyên hesinî yên nermik, şebekeyên pola, û bi sedan materyalên pola yên din.

4. Çima divê hûn ji me bikirin li şûna dabînkerên din?

Çavkaniyên bilind ên pîşesaziya pola ya Çînê yek bikin da ku ji xerîdaran re hilberên pola yên bi kalîte bilind peyda bikin.

Bihayê baş e û kelûpel dikarin di wextê xwe de radestî xerîdaran werin kirin.

5. Em dikarin çi xizmetan pêşkêş bikin?

Mercên radestkirinê yên qebûlkirî: FOB, CFR, CIF, EXW, FCA, DDP, DDU, Express;

Pereyên dayinê yên pejirandî: USD, Euro, RMB;

Rêbazên dayinê yên pejirandî: T/T, L/C, Karta Kredîyê, Western Union, Pere;

Zimanên ku tên axaftin: Îngilîzî, Çînî, Erebî, Rûsî, Koreyî